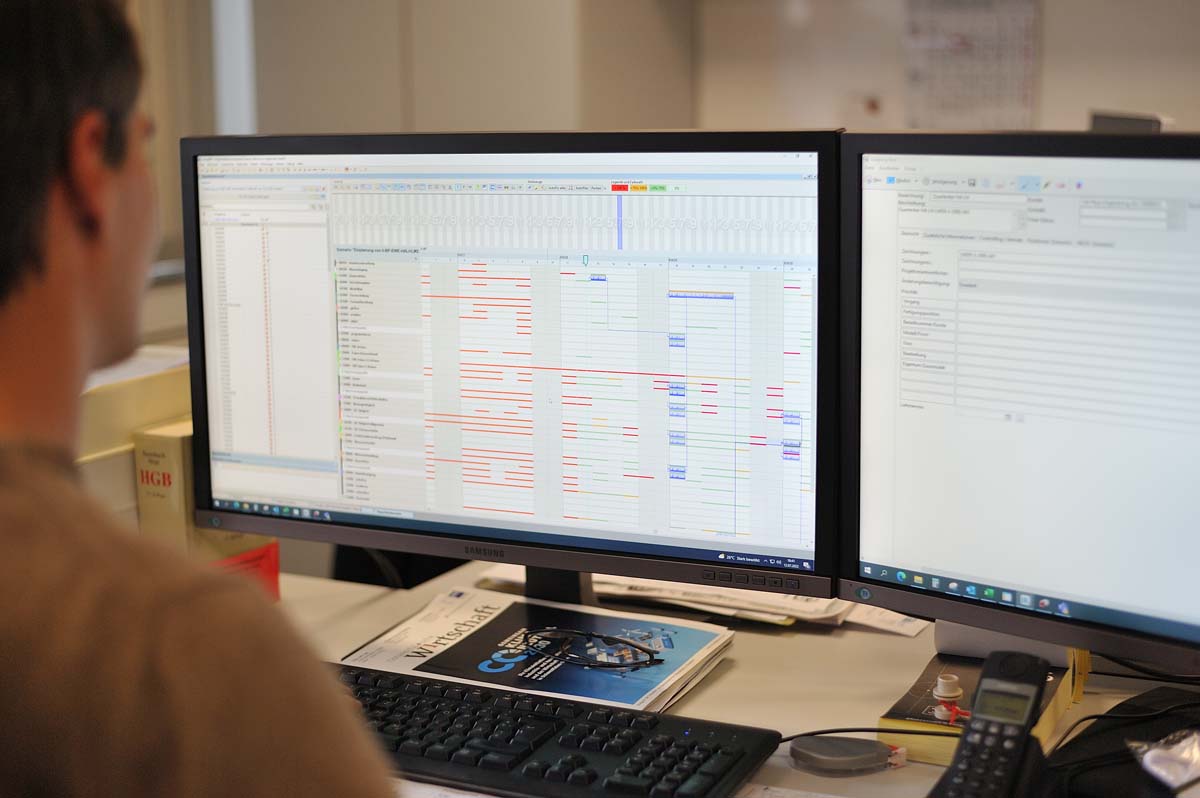

Project management

With the aid of a modern ERP system, our project management oversees the realisation and clarity of your projects. Production is accompanied by detailed work, cost and time scheduling.

Our project management also guides internal production and coordination with our external partners. Our cooperation with these partners over many decades has been defined by quality and trust at the highest level.

Castings

Our rapid prototyping enables the production of your castings in small batches of up to 10 parts within the shortest possible time. This modern process saves you time and money, as 3D printing dispenses with sand casting moulds created through classic pattern making. As casting is conventional, it delivers close-to-series quality components. The process therefore offers a great deal of latitude for further development and adaptation of your castings.

In addition to rapid prototyping, we also provide conventional sand casting, including pattern making. Our perfectly functioning network enables us to observe a short delivery period. Components in these small series provide our customers with important knowledge and insights that are then reflected in later series production.

Together with you, we dicide which process will deliver the best results for your requirements

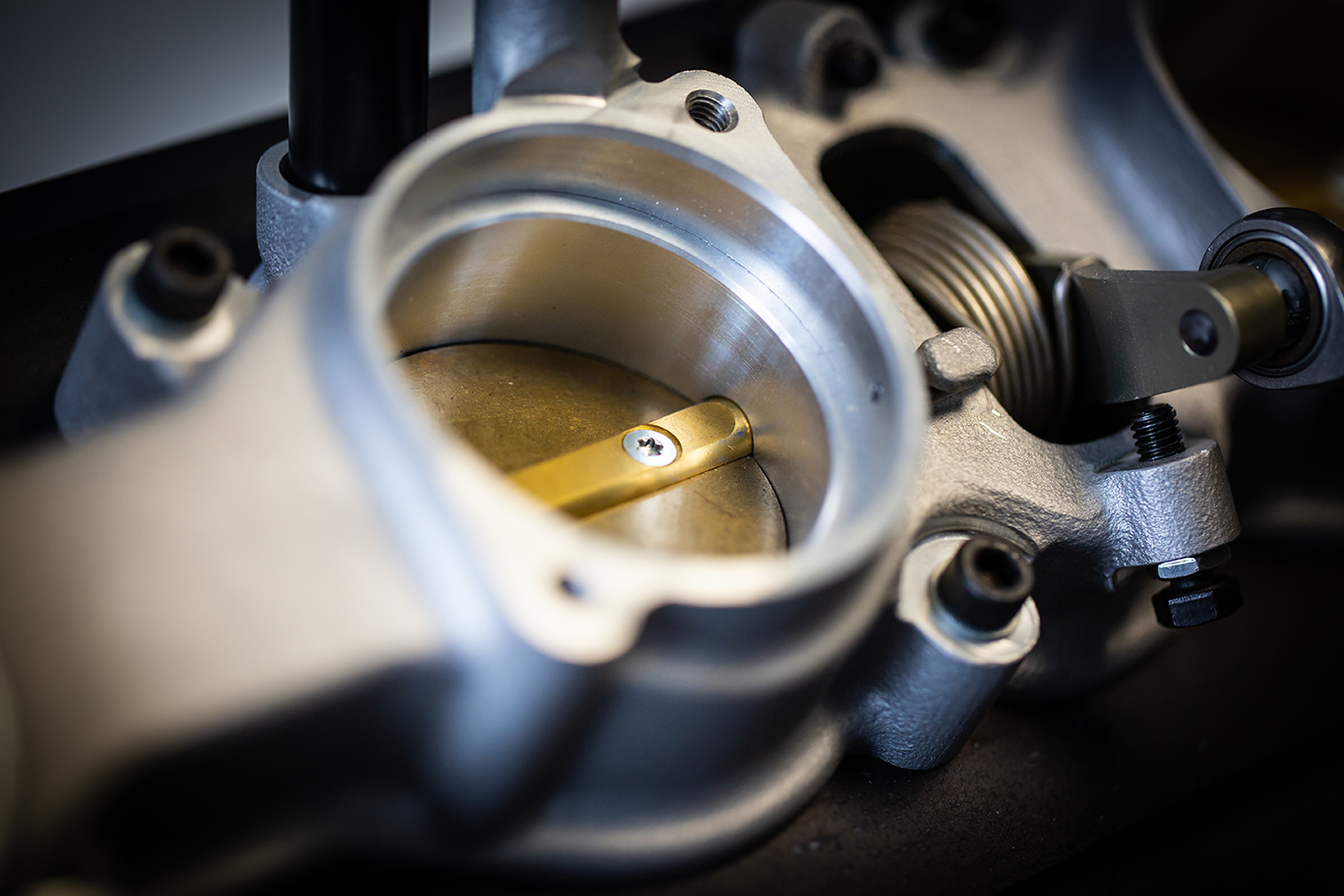

Machined parts

Regardless of whether we are machining castings, free-form parts or components from a variety of metals and noble metals, we realise all machined parts to the highest precision and quality levels. Our highly qualified employees turn, mill and sand the machined parts you desire to series production quality with the aid of our state-of-the-art machinery. This combination of varied and highly complex machining processes is an expression of our single-source service, with everything realised in our company or with the assistance of our experienced partner network.

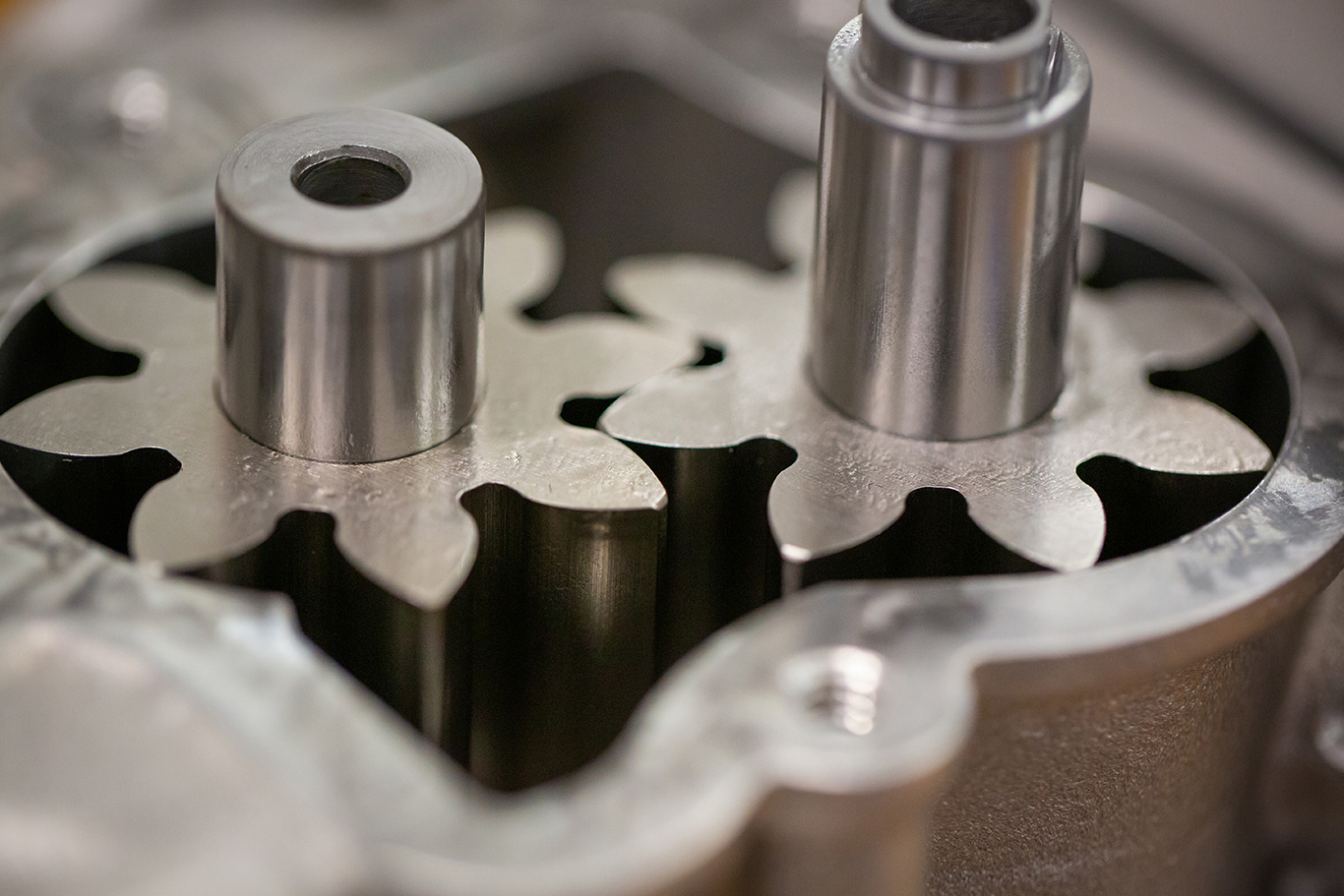

Gears

Welded assemblies

The realisation of welded assemblies demands a maximum degree of precision. You can expect this standard during both design of the welding jigs and the individual manufacture of complete welded assemblies. X-ray inspection and crack testing are also included.

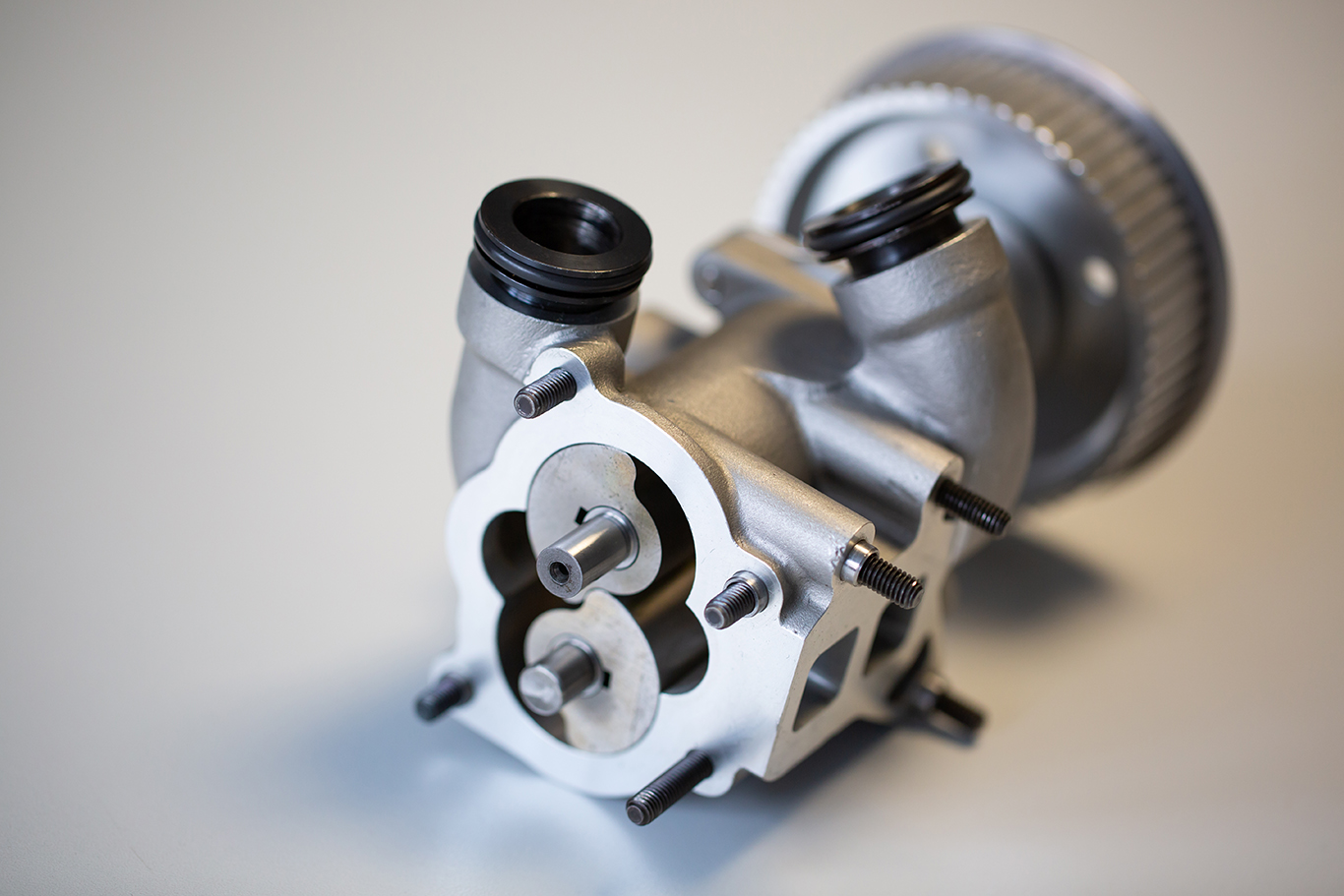

Complete ready-to-install solutions

The combination of our manufacturing options enables us to produce entire assemblies, check their function and deliver these ready for installation. All from a single source.

An example? An oil pump for a vehicle represents a symbiosis of machined castings, geared parts and machined components from the solid. Add to this various heat treatments of individual parts and a variety of surface finishes. All these production steps merge to create the component you require.

Project management

With the aid of a modern ERP system, our project management oversees the realisation and clarity of your projects. Production is accompanied by detailed work, cost and time scheduling.

Our project management also guides internal production and coordination with our external partners. Our cooperation with these partners over many decades has been defined by quality and trust at the highest level.

Castings

Our rapid prototyping enables the production of your castings in small batches of up to 10 parts within the shortest possible time. This modern process saves you time and money, as 3D printing dispenses with sand casting moulds created through classic pattern making. As casting is conventional, it delivers close-to-series quality components. The process therefore offers a great deal of latitude for further development and adaptation of your castings.

In addition to rapid prototyping, we also provide conventional sand casting, including pattern making. Our perfectly functioning network enables us to observe a short delivery period. Components in these small series provide our customers with important knowledge and insights that are then reflected in later series production.

Together with you, we dicide which process will deliver the best results for your requirements

Machined parts

Regardless of whether we are machining castings, free-form parts or components from a variety of metals and noble metals, we realise all machined parts to the highest precision and quality levels. Our highly qualified employees turn, mill and sand the machined parts you desire to series production quality with the aid of our state-of-the-art machinery. This combination of varied and highly complex machining processes is an expression of our single-source service, with everything realised in our company or with the assistance of our experienced partner network.

Gears

Welded assemblies

The realisation of welded assemblies demands a maximum degree of precision. You can expect this standard during both design of the welding jigs and the individual manufacture of complete welded assemblies. X-ray inspection and crack testing are also included.

Complete ready-to-install solutions

The combination of our manufacturing options enables us to produce entire assemblies, check their function and deliver these ready for installation. All from a single source.

An example? An oil pump for a vehicle represents a symbiosis of machined castings, geared parts and machined components from the solid. Add to this various heat treatments of individual parts and a variety of surface finishes. All these production steps merge to create the component you require.

Lütgemeier GmbH // Lange Straße 21 // 33803 Steinhagen // Tel: +49 (0) 5204 91 42 42 // Mail: mail@luetgemeier.de